Mining

KASIYA TEST PIT REHABILITATION TRIALS DELIVER EXCEPTIONAL FIRST YEAR RESULTS

October 08, 2025 / Marcel Chimwala

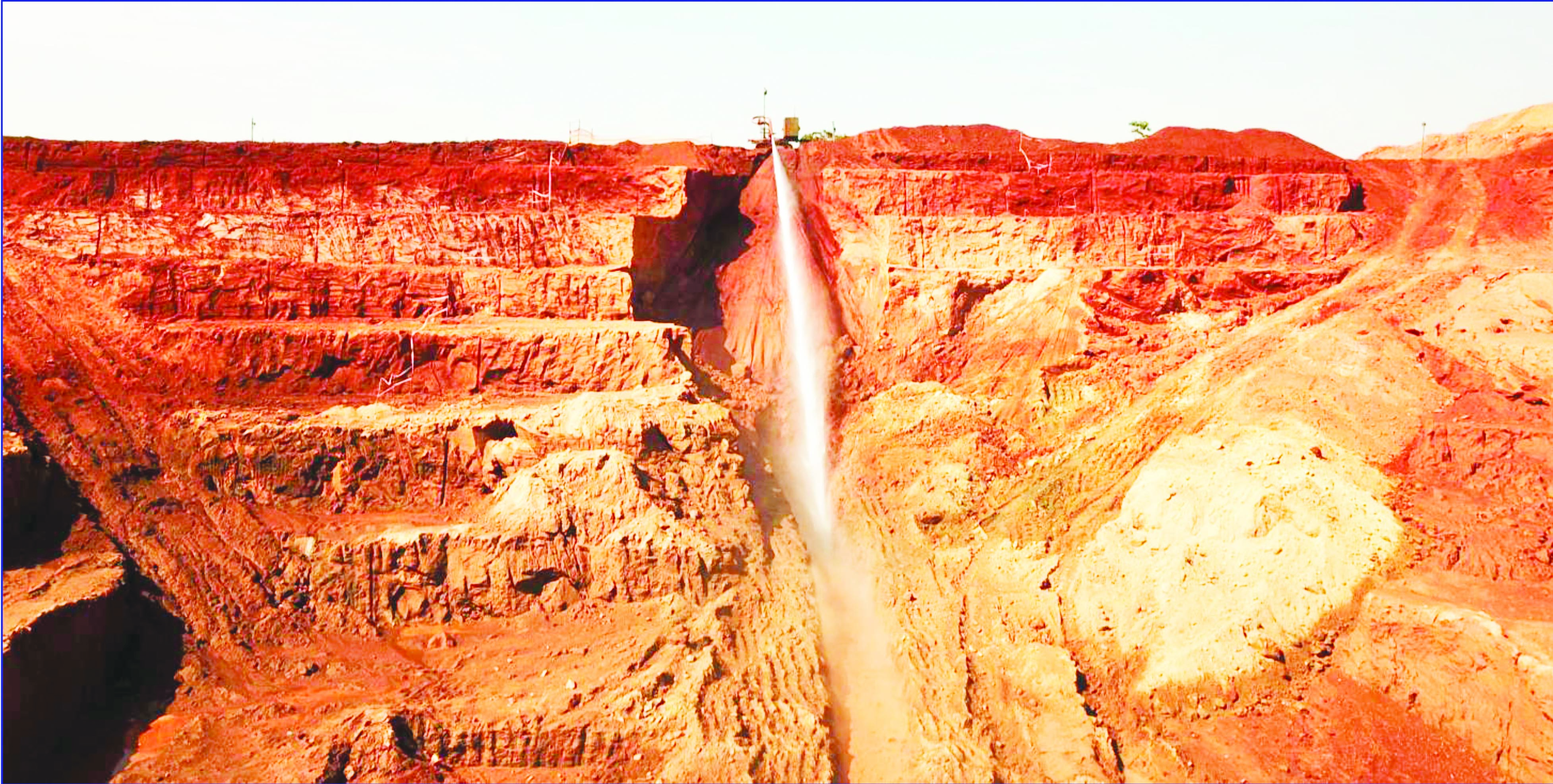

Test pit site during the mining trials (September 2024)

ASX-listed Sovereign Metals has announced exceptional first-year results from its rehabilitation trials at the Kasiya Rutile Graphite Project in Lilongwe, delivering critical data that will inform the progressive rehabilitation strategy for the ongoing Definitive Feasibility Study (DFS).

MD for Sovereign Metals Frank Eagar says in a Press Statement that the successful rehabilitation trials address a key component of Kasiya's development pathway, demonstrating that post-mining land can achieve superior agricultural productivity compared to pre-mining conditions.

Eagar explains that with maize yields of 5.2 tonnes per hectare versus the regional average of 1 tonne per hectare, the trials validate Sovereign's progressive mining, back-filling and rehabilitation approach that will be integrated into the DFS.

He says: "These outstanding rehabilitation results represent another critical milestone in our systematic approach to developing Kasiya into a Tier 1, low carbon, sustainable operation. The empirical data from these trials directly informs our DFS rehabilitation strategy, further de-risking the project while demonstrating exceptional ESG (Environmental, Social and Governance) credentials.”

“With oversight from the joint SVM – Rio Technical Committee, we continue to advance the genuine Tier 1 Kasiya Project.”

Sovereign Metals’ Rehabilitation Lead and Environmental Manager Marco Da Cunha comments that the Company is fully committed to rehabilitating all disturbed land so it can be used for sustainable agricultural activities well beyond the mine life.

“We partnered with local farmers where we successfully tested several rehabilitation options to develop a model for agronomic-driven soil rehabilitation to be adopted by Sovereign during mining,” says Da Cunha.

Successful rehabilitation results further de-risk DFS

The 10-hectare pilot program achieved a 5-times crop yield improvement through soil remediation, engaging 28 local farmers as partners and proving the rehabilitation process to be effective for a scaled-up implementation.

Sovereign followed a systematic six-step rehabilitation process that successfully restored the disturbed land back to productive agricultural use including:

- Land preparation with complete backfill and grading to original contours.

- Soil nutrient enhancement via application of locally sourced lime, biochar and fertilisers.

- Mechanical integration using community-sourced equipment.

- Strategic planting of bamboo blocks with intercropped maize and legumes.

- Harvest success delivering 5.2 tonnes/hectare average yield

- Year-round productivity enabled by drip irrigation for winter farming programs.

The rehabilitation approach combines proven agronomic practices with innovative techniques, including biochar application, precision nutrient management, and intercropping with Giant Bamboo – creating a replicable model for the broader Kasiya development. These rehabilitation results will be integrated into Sovereign's progressive rehabilitation strategy within the DFS, supporting:

- Project-specific closure provisioning through demonstrated restoration success.

- Enhanced community value proposition via improved post-mining land productivity.

- Proven environmental stewardship.

- Strengthened ESG positioning.

Community partnership model

Eagar explains that the trials established a proven framework for community engagement that will scale across Kasiya's development.

Sovereign secured the 10-hectare trial site through a two-year lease from local farmers. The Company worked together with the local farmers to remediate the soils, and plant bamboo and maize crops, deliberately favouring local labour over advanced mechanisation to maximise local benefits.

Eagar says this approach allowed both Sovereign and farmers to directly experience the rehabilitation trials and learn key lessons together, with the land to be returned to the farmers once the 2025-2026 farming season harvest is collected.

“This collaborative approach has strengthened Sovereign's social license by building long-term stakeholder support, creating a replicable model with a systematic approach ready for broader implementation across the Project,” he says.

Overview

Sovereign discovered Kasiya in 2019 after identifying the potential of a new rutile province in Malawi. Today, Kasiya stands out as the world’s largest known natural rutile deposit and second largest known flake graphite deposit and holds the accolade of one of only 11 Tier 1 mining projects discovered in the last decade.

The Kasiya Rutile-Graphite deposit is in an area northwest of Malawi’s capital Lilongwe called the Lilongwe Plain. Kasiya is the largest rutile deposit in the world with a Mineral Resource Estimate of 1.8Bt at 1.0% rutile resulting in 17.9Mt tonnes of contained natural rutile.

Rutile is the purest, highest-grade naturally occurring form of titanium. Titanium serves a range of industrial markets due to its remarkable properties. Titanium is highly corrosion resistant and chemically inert while offering a high strength-to-weight ratio. In its form as titanium dioxide, titanium feedstock is also essential for pigment manufacturing, for example in paints and paper.

In its metal form, titanium is as strong as steel, but 45% lighter, and twice as strong as aluminium, but only 60% heavier. As a result, the metal is used extensively in aerospace, defence, healthcare, and technology applications.

Graphite is a naturally occurring crystalline form of the element carbon. Occurring within rutile mineralisation, graphite is a “by-product” from Kasiya. Kasiya is the second largest flake graphite deposit in the world with a Mineral Resource Estimate of 1.8Bt at 1.4% graphite resulting in 24.4Mt tonnes of contained natural graphite.

Graphite is used in multiple industries, but demand in batteries is the high-growth area. With Kasiya’s natural graphite being suitable for the manufacture of active anode material, the Project is set to become the largest secure long term source of supply outside of China, producing natural graphite at an industry low operating cost.